For the team, each private aircraft interior design starts with the client. The team work tirelessly to carefully define the style, purpose and requirements of the aircraft interior. This ensures the creation of a fit for purpose interior, perfectly matched to an individual’s tastes and considerations. The results of this approach are simple, beautifully crafted aircraft interiors, which perform.

When it comes to aircraft interior design, a one size fits all approach does not work, that’s why prior to starting any design project, our team carries out a full needs analysis. The analysis required covers a variety of topics including:

The answers to the above remain at the forefront of the minds of our design team, who excel in matching exclusive materials and interiors to a diverse set of clients, which have included: sports teams, royalty, businesses and individuals. Expertise at all stages of the process ensures that every design produced is fully compliant with aviation regulations.

Taking into consideration each unique requirement, dreams and ideas are turned into a reality with the use of 3D and 2D modelling. At this concept stage the interior will represent an interior which mirrors personal tastes, in a layout optimised for both functionality and comfort.

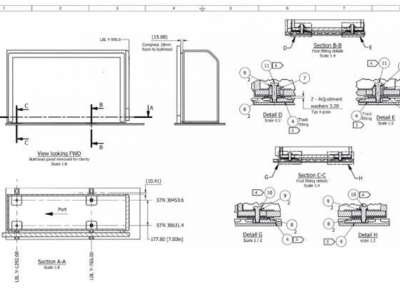

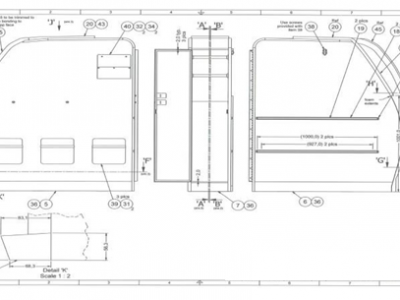

Further utilising techniques, such as 3D modelling and technical drawings, are used to draft a list of requirements. This specification is a key phase in turning an aircraft interior dream into a reality. The specification contains all technical and electrical drawings, as well as materials and products which are to be used – which may include lighting, appliances and features.

Over the last 8 years, we have worked hard to build up strong relationships with the world’s leading aircraft interior suppliers. Furthermore, our extensive facilities include airside design office, workshop and hangar which allows us to manufacture many components in house. Our in house capabilities include: fabrication, soft furnishings and composite manufacturing, as well as the ability to create all levels of interior paint finishes, VVIP wood veneers and lacquers.

This unique approach allows us to create perfectly designed, manufactured aircraft components of an unrivalled durability, which simply aren’t available as off the shelf products.